Solar Collectors

Solar panels may be installed in thermosiphonic or in central (forced circulation) solar systems.

- The high quality material, used for collectors manufacture, guarantee a long lasting unimpeded function and high efficiency.

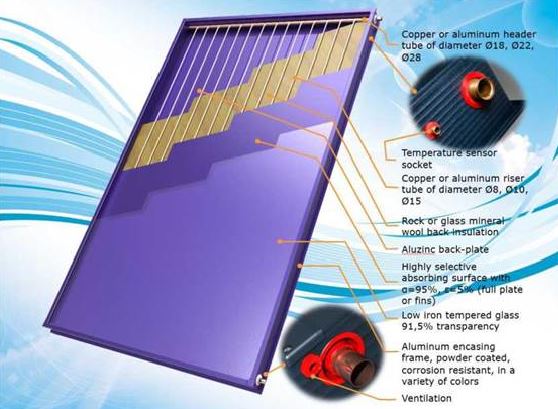

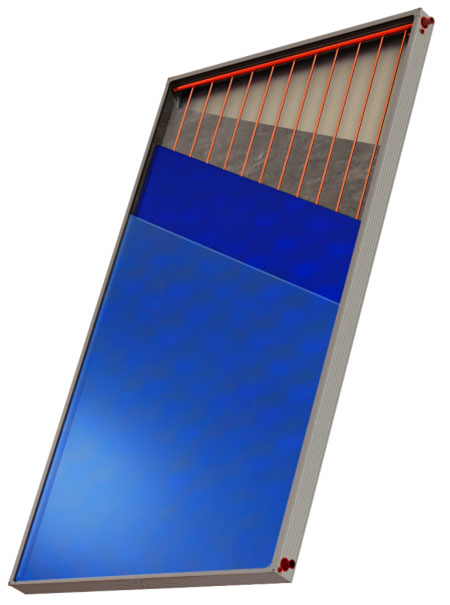

- The absorbing surface consists of aluminum 0,5mm thick, with super-selective blue titanium coating with high absorption rate and minimal emission of incident solar radiation (a=95%, e=5%). The selective materials of the absorber that we use are TinoxEnergy or MirothermalAlanod

- The absorber’s hydroplate consists of a copper tube Ø8x0,40mm and headers are also copper tubes of Ø33x0,7mm. The specific models have 9 or 11 vertical tubes. The horizontal models have 18 vertical tubes. The copper tubes type is DHP in compliance with standard EN12449.

- Hydroplate type: Arpa

- Laser welding guarantees the perfect thermal transfer from the absorbing surface to the hydroplate.

- All absorbers of our production are tested at a 7 and 15 bar pressure (2 successive pressure tests) for leakage control and solder strength.

- The insulation consists of high quality rock wool, especially for solar collectors, 30mm thick and density of 50kg/m3. Side insulation is 20mm thick.

- The cover on the front of the collector is a safety glass of 91,5% and permeability 3,2mm thick.

- The collector frame is made of aluminum with an electrostatic paint coating for maximum resistance in seaside areas and generally in areas with extreme weather conditions. The following colors are available: RAL 9006 light metallic grey, RAl 9007 dark metallic grey, black, brown, dark metallic blue. Other colors are available upon request.

- The rear cover is 0,4mm thick Aluzinc, with the highest corrosion resistance (7 times more durable than the common galvanized steel sheet).

- The waterproof materials are EPDM, silicone and polyurethane mastic for maximum resistance to extreme temperatures and absolute dryness of the collector.

- Collectors have 2 ventilation points for perfect operation.

|

COLLECTORS TECHNICAL DATA / SPECIFICATIONS |

|||||||||||||||||

|

Model |

1.50 V |

1.50 H |

1.82 V |

1.82 H |

2.00 V |

2.00 H |

2.37 V |

2.37 H |

2.72 V |

2.72 H |

|||||||

|

Gross area [m2] |

1.50 |

1.50 |

1.82 |

1.82 |

2.00 |

2.00 |

2.37 |

2.37 |

2.72 |

2.72 |

|||||||

|

Total Dimensions [mm] |

L:1480 W:1010 H:86 |

L:1010 W:1480 H:86 |

L:1480 W:123 H:86 |

L:1230 W:1480 H:86 |

L:1980 W:1010 H:86 |

L:1010 W:1980 H:86 |

L:1930 W:1230 H:86 |

L:1230 W:1930 H:86 |

L:2160 W:1260 H:86 |

L:1260 W:2160 H:86 |

|||||||

|

Max. operating Pressure [bar] |

10 |

||||||||||||||||

|

Thermal Liquid Capacity [It] |

1.21 |

1.50 |

1.50 |

1.65 |

1.40 |

2.05 |

1.70 |

2.16 |

1.85 |

2.35 |

|||||||

|

Collector front Cover-Thickness |

LOW IRON TEMPERED GLASS 3.2mm |

||||||||||||||||

|

Casing Material |

ALUMINUM POWDER COATED |

||||||||||||||||

|

Sealing Materials |

POLYURETHANE SEALANT- SILICON - EPDM |

||||||||||||||||

|

Air Vents-Sealing Washers |

EPDM-SILICON |

||||||||||||||||

|

Absorber Area [m²] |

1.38 |

1.38 |

1.72 |

1.72 |

1.87 |

1.87 |

2.23 |

2.23 |

2.57 |

2.57 |

|||||||

|

Absorber Material- Treatment |

ALUMINUM / PVD COATING / HIGH SELECTIVE - A=0.95 ± 0.02 / e= 0.05 ± 0.02 |

||||||||||||||||

|

Absorber construction Type |

LASER WELDING |

||||||||||||||||

|

Heat transfer Medium |

PROPYLENE GLYCOL + WATER MIXTURE |

||||||||||||||||

|

Tests and Certifications |

SOLAR KEYMARK |

||||||||||||||||

|

EFFICIENCY VALUES BASED ON EN12975 STANDARD (BASED ON ABSORBER AREA) |

|||||||||||||||||

|

Efficiency η0 |

0,788 |

||||||||||||||||

|

Thermal loss a1a [w/(m2K) ] |

5,140 |

||||||||||||||||

|

Thermal loss a2a (w/(m2K2 ) |

0.017 |

||||||||||||||||

|

Stagnation temp. [°C] |

152 |

||||||||||||||||